Direct cooling low-temperature refrigeration unit

The PTZL series direct cooling low-temperature refrigeration unit uses a temperature of -60 ℃ and is mainly composed of a refrigeration system, a condensation recovery system, a control system, and a box. The refrigeration system adopts steam compression refrigeration. The condensation recovery system consists of evaporative coils, recovery storage tanks, refrigeration pipelines, etc. The control system adopts mechanical buttons and temperature instruments for startup control, with multiple protection functions to ensure the safe operation of the equipment. Through the refrigeration of the unit itself, the recovered gas entering the device is cooled and condensed to meet the requirements of the process conditions.

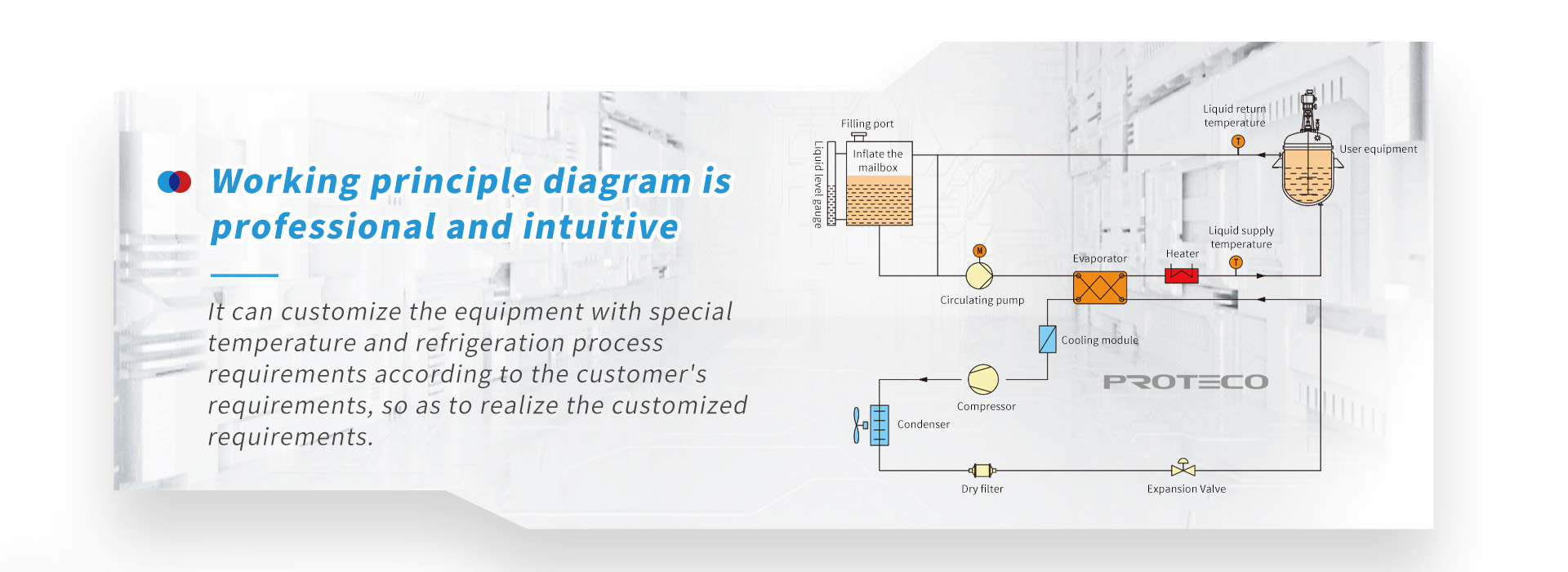

Refrigeration system: Double compressor cascade refrigeration system, ensuring long-term stable operation, convenient maintenance, safety and reliability.

Efficient heat exchange system: The intermediate heat exchanger and subcooler both use high-efficiency plate heat exchangers, which have high heat exchange efficiency and compact structure.

Control repeatability: Based on a reliable control system, consistent control results can be achieved every time, greatly improving the stability of product production.

Ultra high temperature cooling technology: Adopting ultra-high temperature cooling technology, it can directly start the compressor for cooling at a maximum temperature of 60 ℃.

Quality assurance: All key components are selected from imported brands or domestic first tier brands to ensure long-term reliable operation of the products. At the same time, all products undergo strict testing and inspection before shipment to ensure that there are no problems with the equipment when it arrives at the customer's site.

Consult immediately

Complete order

Complete order Print invoice

Print invoice Packaging and packing

Packaging and packing Free logistics

Free logistics Free installation/debugging

Free installation/debugging