Liquid cooler

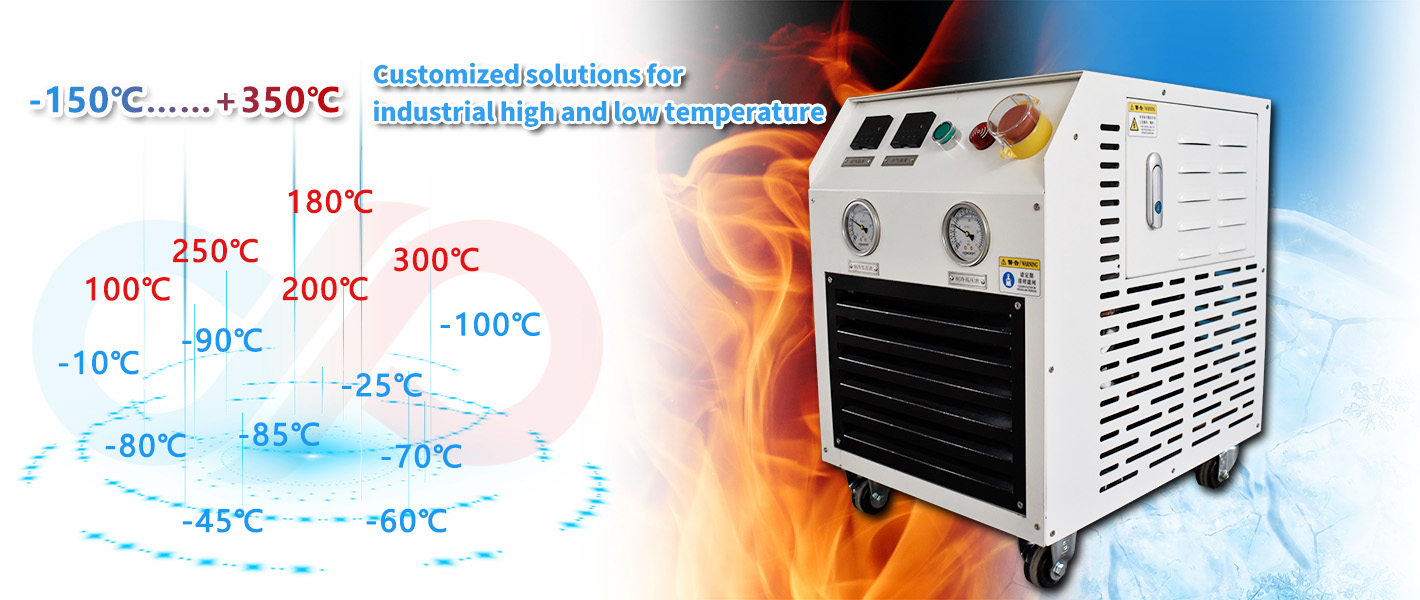

The PTLQ series gas refrigeration machine is mainly composed of a refrigeration system, a heat exchange system, a control system, a casing, etc. The refrigeration system adopts steam compression refrigeration

The PTLQ series gas refrigeration machine is mainly composed of a refrigeration system, a heat exchange system, a control system, a casing, etc. The refrigeration system adopts steam compression refrigeration

Applied to the heating and cooling of wafer testing platforms and Chuck, using silicone oil or fluorinated liquid circulation for precise temperature control of ± 0.1 ℃. The liquid cooler mainly consists of a heating circulation system, cooling system, control system, box, etc. By heating and cooling the unit itself, the heat carrying fluid is transported to the outside world to meet the process conditions.

Applied to the heating and cooling of wafer testing platforms and Chuck, using silicone oil or fluorinated liquid circulation for precise temperature control of ± 0.1 ℃. The liquid cooler mainly consists of a heating circulation system, cooling system, control system, box, etc. By heating and cooling the unit itself, the heat carrying fluid is transported to the outside world to meet the process conditions.

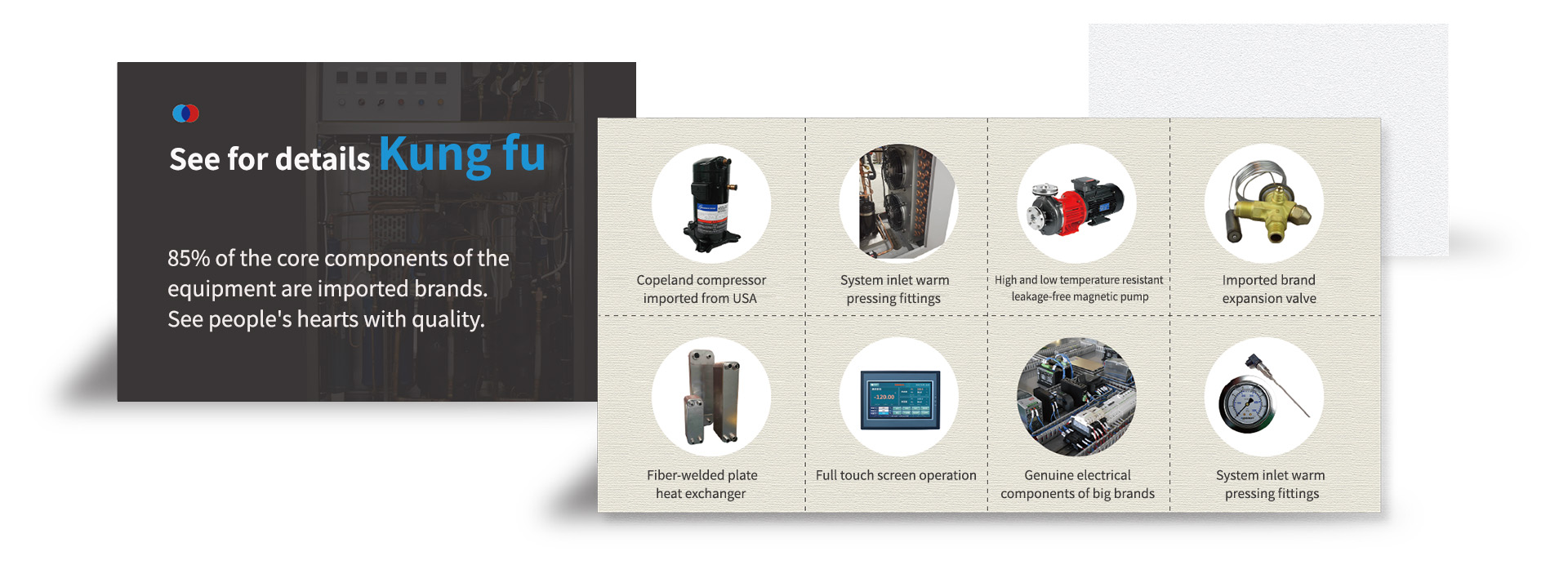

The PTLD series low-temperature freezer mainly consists of a refrigeration system, a circulation system, a control system, a box, and so on. The refrigeration system adopts steam compression refrigeration, and the compressor and main refrigeration components are all from internationally renowned brands.

The PTLD series low-temperature freezer mainly consists of a refrigeration system, a circulation system, a control system, a box, and so on. The refrigeration system adopts steam compression refrigeration, and the compressor and main refrigeration components are all from internationally renowned brands.

Semiconductor thermoelectric cooler, also known as semiconductor chiller, semiconductor temperature control console, precision semiconductor cooler, is composed of semiconductor refrigeration system, circulating water cooling system, temperature control system, and measuring fixture platform. Widely used in semiconductor industry etching devices, CMP laboratory precision devices, high-precision testing instruments, etc

Semiconductor thermoelectric cooler, also known as semiconductor chiller, semiconductor temperature control console, precision semiconductor cooler, is composed of semiconductor refrigeration system, circulating water cooling system, temperature control system, and measuring fixture platform. Widely used in semiconductor industry etching devices, CMP laboratory precision devices, high-precision testing instruments, etc

The PTCU series of Putek TCU temperature control units explores and utilizes various existing main energy sources, such as hot oil, steam, frozen saline water, and cold oil, for temperature control in mixing tanks, chemistry, pharmaceuticals, bioreactors, material testing research, and production. A TCU temperature control unit system can meet the temperature control requirements of different processes in multiple reactors. The purpose is to integrate existing systems and fully utilize existing primary energy sources.

The PTCU series of Putek TCU temperature control units explores and utilizes various existing main energy sources, such as hot oil, steam, frozen saline water, and cold oil, for temperature control in mixing tanks, chemistry, pharmaceuticals, bioreactors, material testing research, and production. A TCU temperature control unit system can meet the temperature control requirements of different processes in multiple reactors. The purpose is to integrate existing systems and fully utilize existing primary energy sources.

OUR

SERVICE

Quality assurance services

Free shipping

Formal invoice

Free installation/debugging

Free door-to-door delivery nationwide: The delivery time varies from 5-7 days in various provinces of northwest, northeast, and southwest. Due to uncertain factors, the delivery time in some places is more than 7 days, while in other provinces it is 3-5 days. The delivery time in Jiangsu, Zhejiang, and Shanghai is 1-2 days

We do not make any promises regarding transportation time. In the event of holidays, rain, snow, heavy fog, etc., there may be occasional delays in logistics transportation, which is beyond the manufacturer's control. Please understand.

Complete order

Complete order Print invoice

Print invoice Packaging and packing

Packaging and packing Free logistics

Free logistics Free installation/debugging

Free installation/debugging