Liquid cooled refrigeration unit

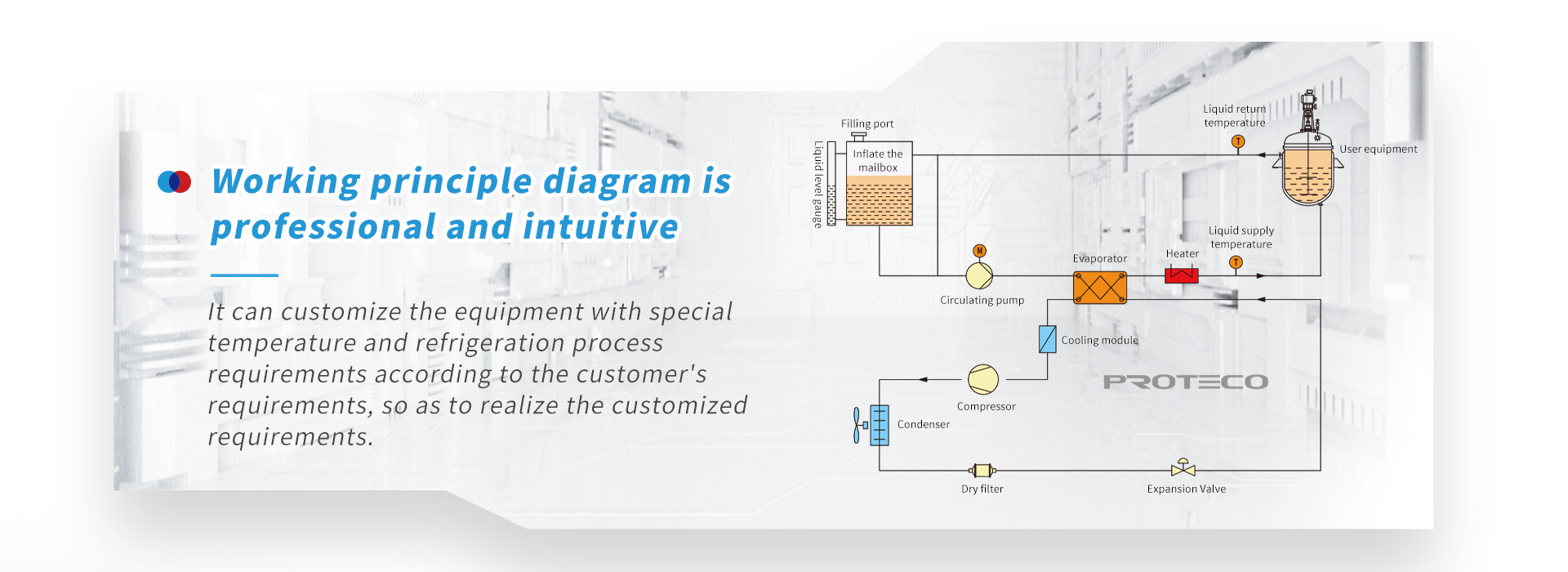

Applied to the heating and cooling of wafer testing platforms and Chuck, using silicone oil or fluorinated liquid circulation for precise temperature control of ± 0.1 ℃. The liquid cooler mainly consists of a heating circulation system, cooling system, control system, box, etc. By heating and cooling the unit itself, the heat carrying fluid is transported to the outside world to meet the process conditions.

Complete order

Complete order Print invoice

Print invoice Packaging and packing

Packaging and packing Free logistics

Free logistics Free installation/debugging

Free installation/debugging