gas refrigerator

Provide accurate and fast ambient temperature for chips, modules, integrated circuit boards, electronic components, etc. Replacing liquid nitrogen to provide rapid cooling for local heat sources. Provide a cold source for testing the electrical performance, reliability, aging, and other aspects of the product

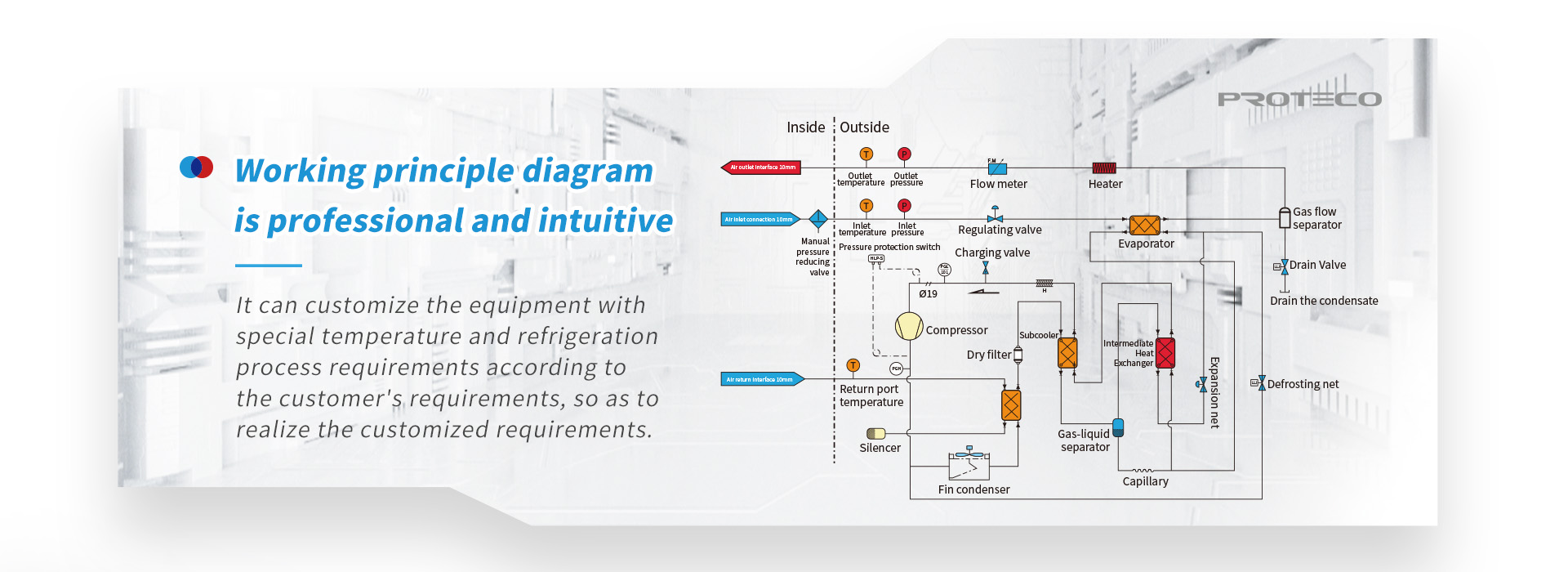

1. Rapid cooling, independently designed high-efficiency heat exchange system;

2. Siemens PLC control, high-definition touch screen display, with multiple protection functions;

3. Dry gas enters the unit for cooling and constant temperature treatment;

4. Integrated structure: The system is assembled as a whole in the factory.

Consult immediately

Complete order

Complete order Print invoice

Print invoice Packaging and packing

Packaging and packing Free logistics

Free logistics Free installation/debugging

Free installation/debugging