Gas cooled wafer testing

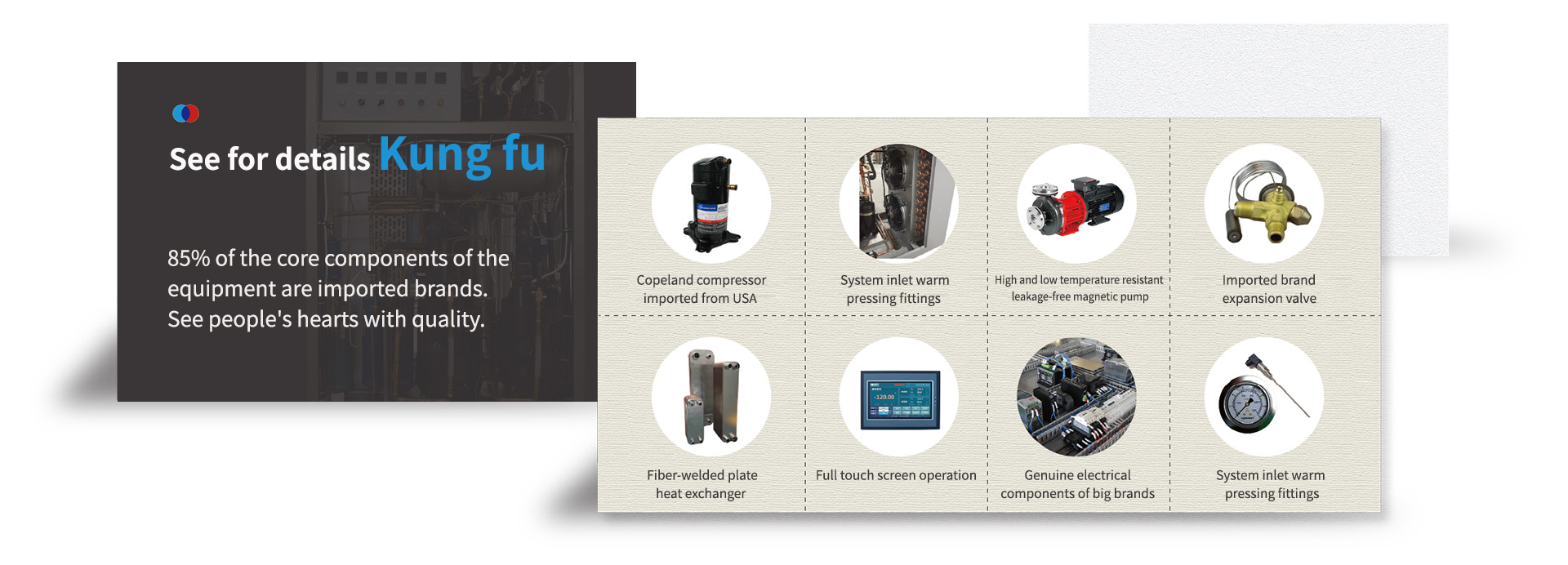

It mainly consists of refrigeration system, circulation system, control system, box, etc. The refrigeration system adopts steam compression refrigeration, and the compressor and main refrigeration components are all from internationally renowned brands. The circulation system consists of a circulation pump, a cold storage container, an exhaust valve, a one-way valve, a thermal resistor, pipelines, etc. The control system adopts PID control technology, high-definition touch screen display, and is equipped with multiple protection functions to ensure the safe operation of the equipment. By cooling and heating the unit itself, the heat carrying fluid is transported to the outside world to meet the requirements of the process conditions.

Fully enclosed system: Adopting a fully enclosed system design, the entire circulation pipeline only has breathing holes left on the liquid cap, and the cooling medium will not directly come into contact with the air, extending the service life of the medium and ensuring the stability of system operation.

Efficient heat exchange system: Plate heat exchangers are used for refrigeration, with high heat exchange efficiency and compact structure.

Repeatability of control results: Based on advanced dynamic control systems, consistent control results can be achieved every time, greatly improving the stability of product production.

Product Appearance: The appearance design draws on the design concept of imported foreign products, using a large caliber quartz glass level gauge. The level gauge and operation screen are placed on the same side for easy observation, simple and fashionable style, coordinated layout, and exclusive color matching.

Consult immediately

Complete order

Complete order Print invoice

Print invoice Packaging and packing

Packaging and packing Free logistics

Free logistics Free installation/debugging

Free installation/debugging