Direct cooling refrigeration machine

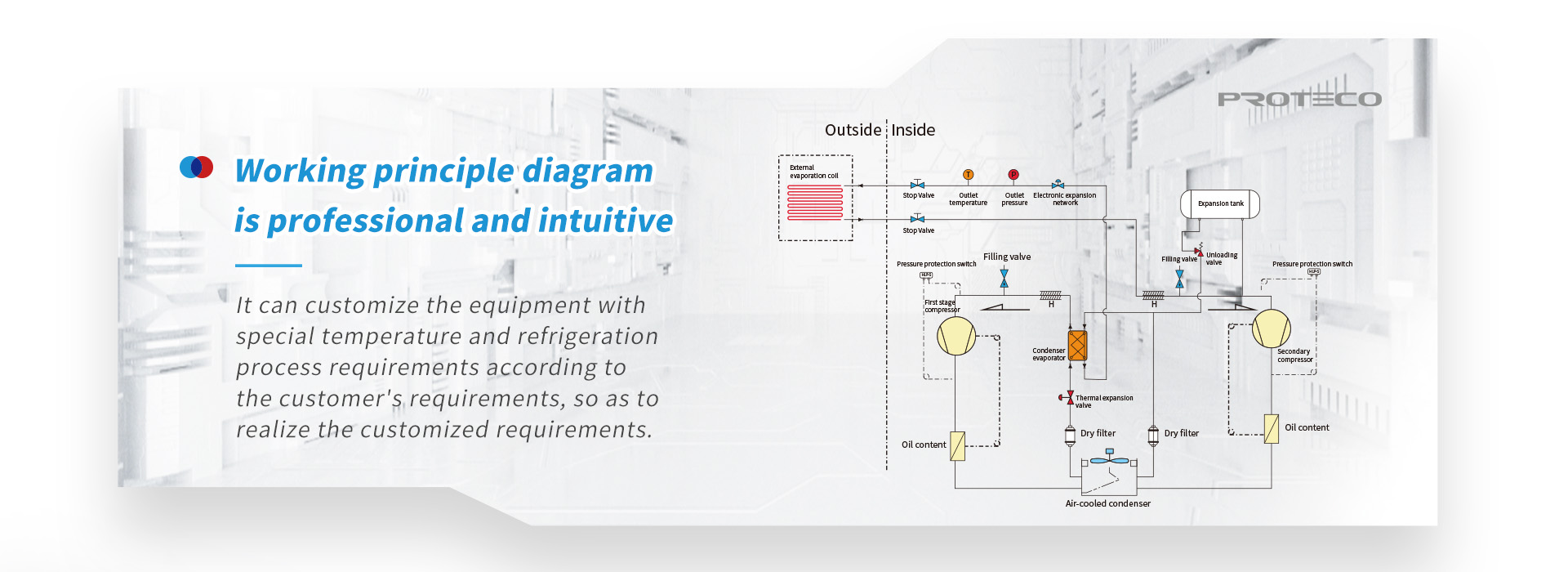

Direct cooling refrigeration machine is a device that directly outputs and evaporates refrigerant from a refrigeration system into a heat exchanger or control chamber element that requires temperature control, thereby rapidly cooling and maintaining a constant temperature of the target equipment

Complete order

Complete order Print invoice

Print invoice Packaging and packing

Packaging and packing Free logistics

Free logistics Free installation/debugging

Free installation/debugging