Automotive thermal management system temperature control system

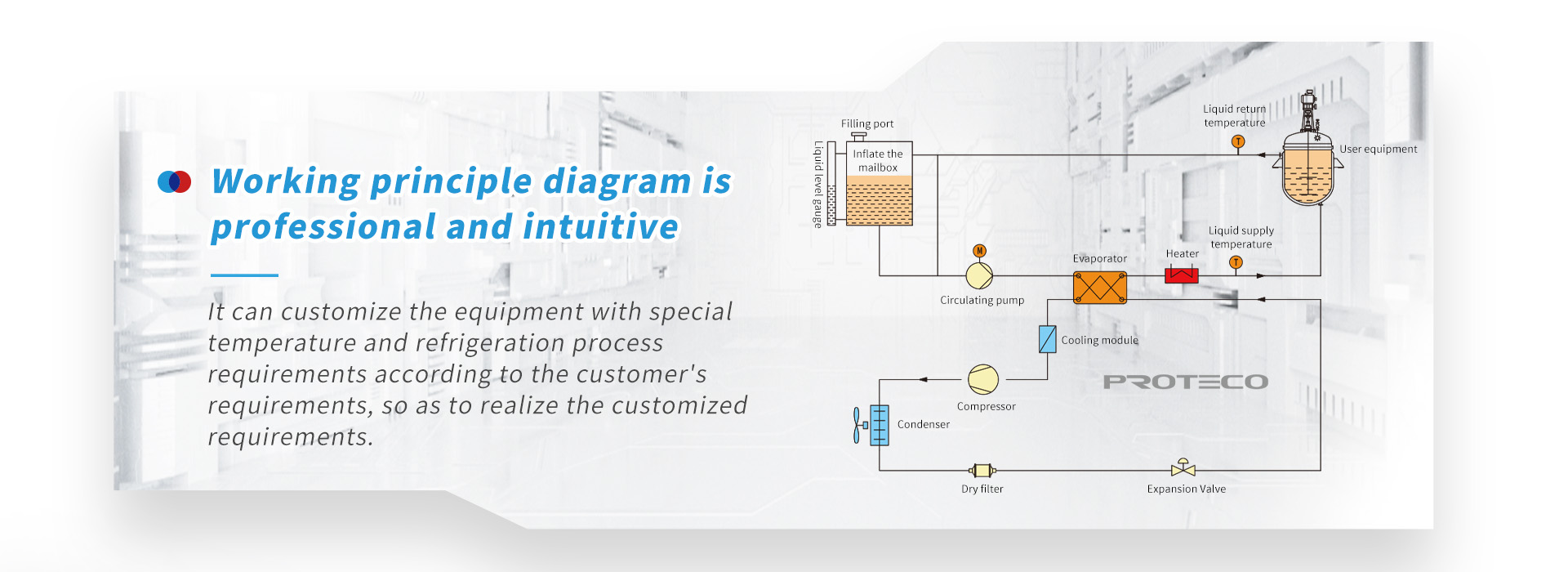

The automotive thermal management system consists of multiple components and heat transfer fluids, including a heat exchanger, fan, coolant pump, compressor, thermostat, sensor, actuator, cooling water jacket, and various pipelines; The heat transfer fluid includes air, coolant, engine oil, lubricating oil, exhaust gas, fuel, refrigerant, etc. These components and fluids must work in coordination to meet the requirements of vehicle heat dissipation and temperature control.

Complete order

Complete order Print invoice

Print invoice Packaging and packing

Packaging and packing Free logistics

Free logistics Free installation/debugging

Free installation/debugging